- Home

- News

- Team

-

Scientific groups

- Scientific group "Natural products for innovative preventive medicine and health" (Natura4Health)

- Scientific group "R&D Laboratory for Food Additives" (SMART)

- Nutrition and Neurosciences (NutriLect)

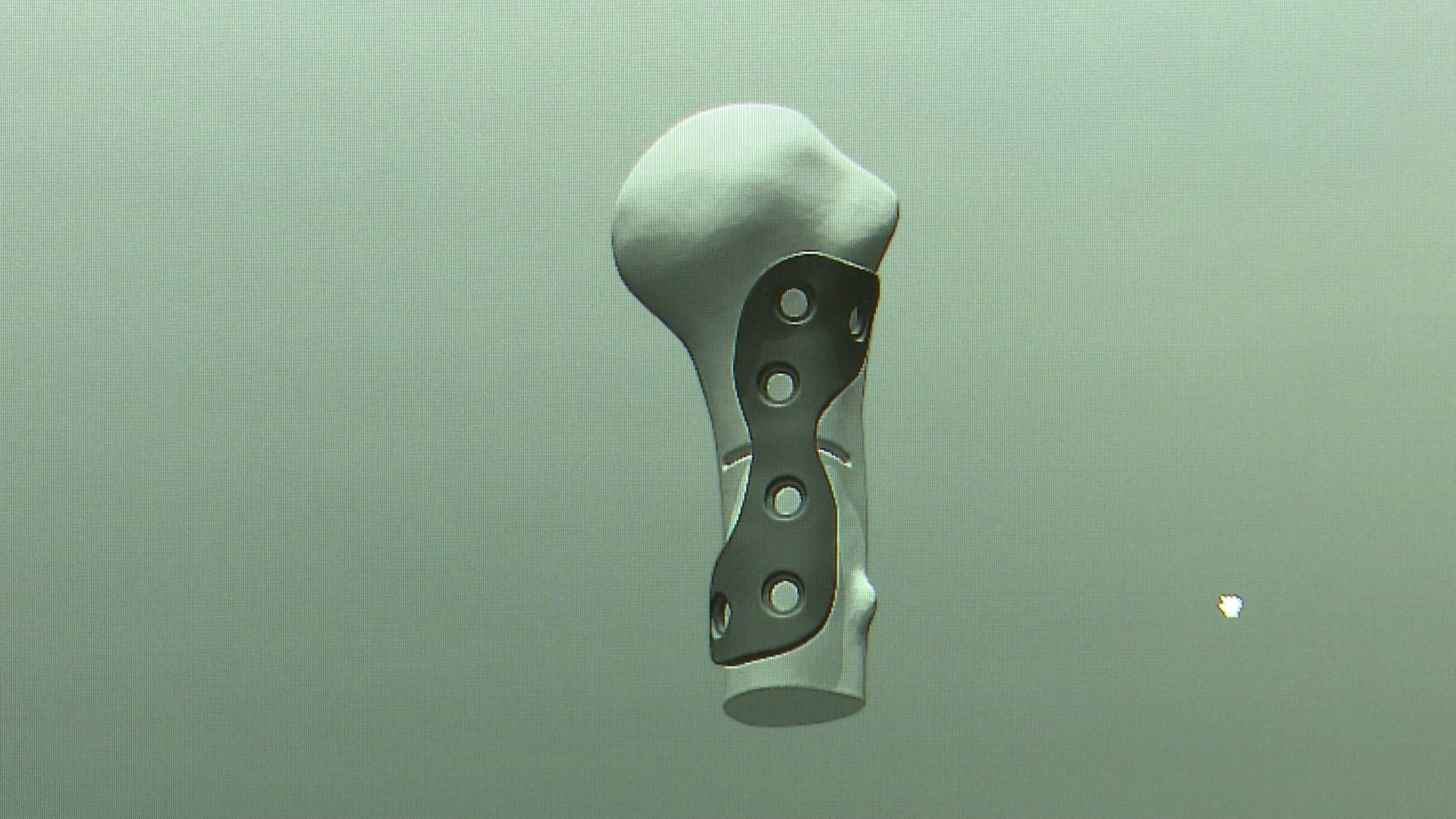

- Customized implants for bone regenerative therapy (PersIm)

- Early Diagnosis and Prevention of Oncological Breast Diseases by Using New Technologies (ELPIDA)

- Application of New Advanced Technologies in Management of Cancer and Rare Diseases (LiquidBio)

- Artificial cornea – from the bench to the bedside and back (AC-3B)

- Obstructive sleep apnea and comorbidity (GOSACD)

- Renal epithelial and vascular aging (RenEVA)

- Contests

- Gallery

- Contacts

For more information, see the video: https://www.youtube.com/watch?v=Z1hswIl1eLQ

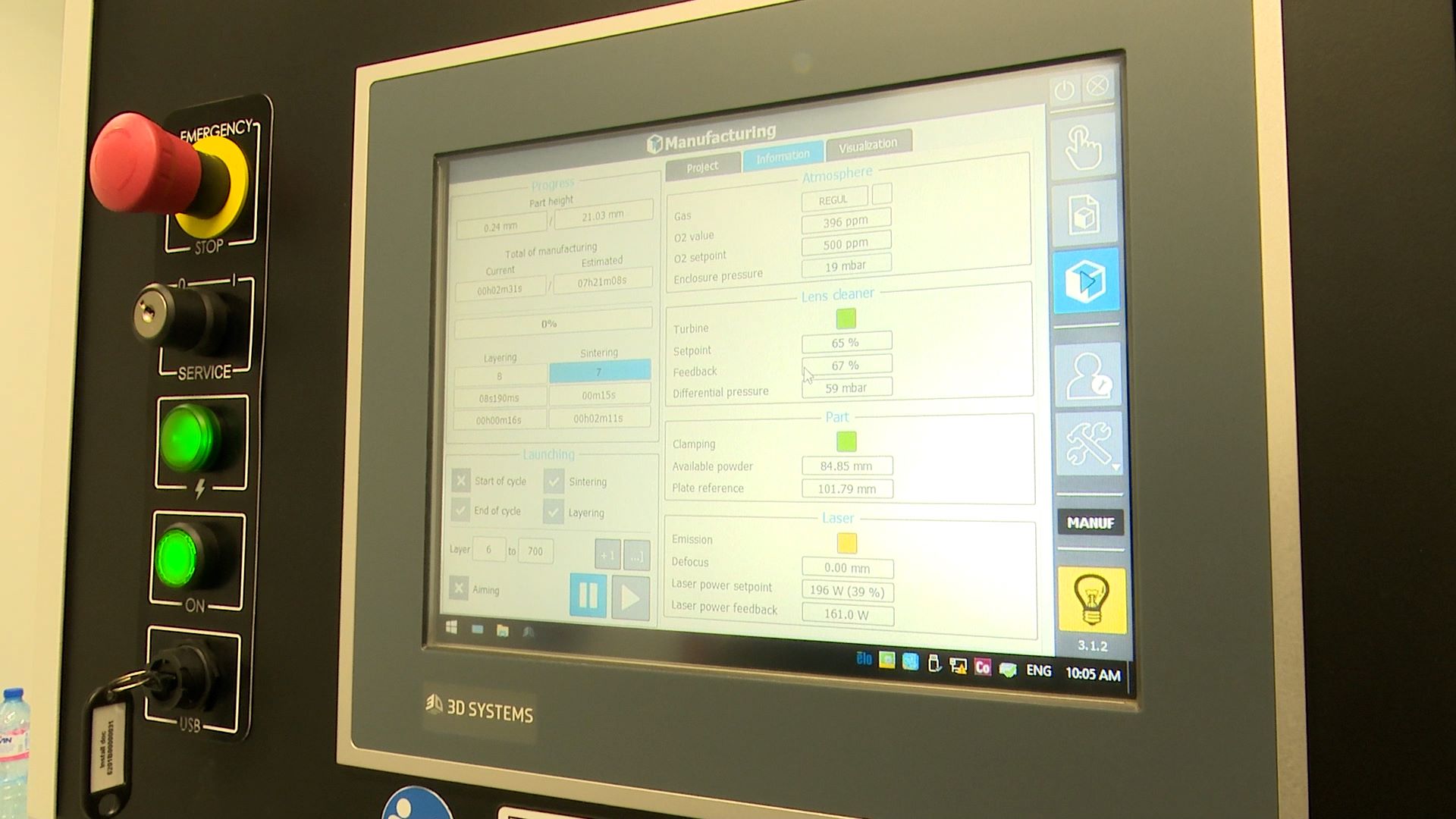

The latest generation of 3D metal printers, which will be used to manufacture personalized implants in various medical fields, is the newest technology in which MU-Varna is investing. The medical equipment was provided under the university's project to enhance translational achievements in medicine (MUVE - TEAM).

"The introduction of this innovative equipment marks the beginning of a new era for all surgical specialties that rely on implantology methods to solve complex diagnostic cases," emphasized the rector of MU-Varna, Prof. Dimitar Raykov, adding: "We are very proud to be leaders in the implementation of this technology; for Varna, this is a great achievement. Until now, it was possible to manufacture implants from other materials, such as polymers and plastics, but they could only be a visual model of what we would operate on or model." Prof. Raykov pointed out that with the new 3D printer, these models can now be directly implanted into the human body.

The Dean of the Faculty of Dental Medicine, Prof. Dr. Stefan Peev, emphasized that with this new acquisition, MU-Varna is taking a big step forward in the development of personalized medicine. "This device for layer-by-layer laser melting will allow the manufacture of personalized implants from titanium and biocompatible titanium alloys, as well as from other materials, such as cobalt-chromium alloy and steel," added Prof. Peev. He emphasized that this will expand the range of applications for implants and increase the quality of patient care. He emphasized that this will broaden the range of applications for implants and improve the quality of patient care. The new 3D printer is already putting Varna at the forefront of implantology, and the university is becoming a leading center for the development of personalized medicine in the region, Prof. Peev pointed out. According to experts, the 3D models will be used as an aid in surgical procedures for complex cases, such as tumors and severe pelvic fractures.

According to experts, the 3D models will be used as an aid in surgical procedures for complex cases—tumors, severe pelvic fractures, and infections—where bone loss is a limiting factor. Dr. Stoyan Ivanov, a specialist in orthopedics and traumatology, emphasized: "Personalized implants ensure better adaptation to the patient's anatomy, which leads to better results and fewer complications. The technology allows us to model complex cases in advance and plan surgical interventions with extreme precision."

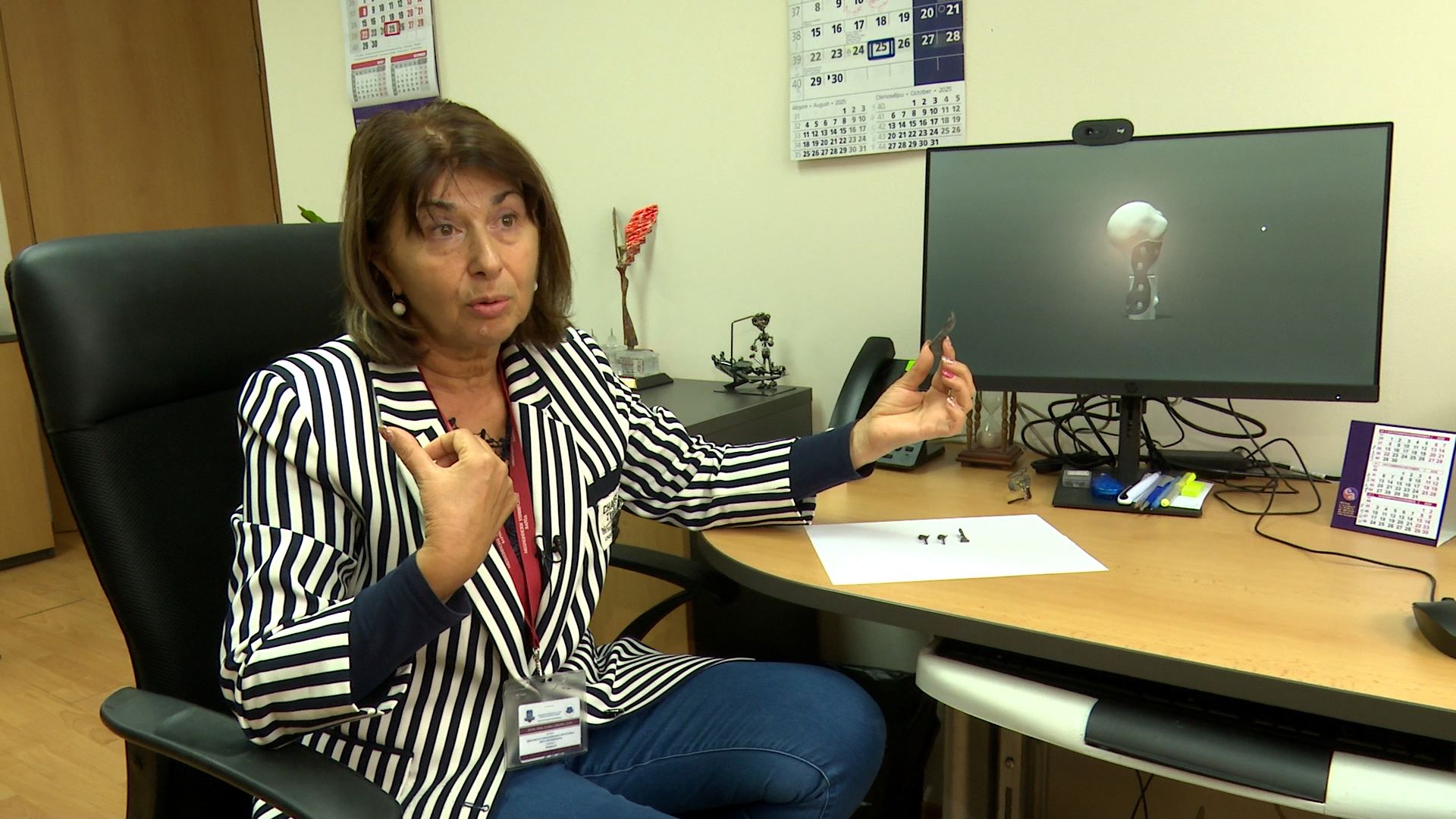

The process of creating personalized implants involves complex preliminary preparation, which begins with virtual modeling of a digital model using specialized software. Prof. Eng. Tsanka Dikova, head of the Dental Materials Science Department at MU-Varna and lead researcher of the Personalized Implants for Bone Regeneration (PersIm) research group on the MUVE-TEAM project, explained: "After creating the digital vision, the laser beam melts the metal powder layer by layer, sculpting the final product." Personalized implants will find application in orthopedics, neurosurgery, otorhinolaryngology, and dental medicine.

For years, the scientific group for personalized implants at MU-Varna has been gaining experience with printed models for preliminary preparation in complex surgical cases. This collaboration with international experts, such as Eng. Gabriela Graziani from Italy and Prof. Boyko Georgiev, Deputy Director of the Research Institute for Osteosynthesis in Davos, contributes to the development of this innovative field.

This new technology is key to the future of surgery and will improve the effectiveness and safety of treatment, bringing hope to patients with the most complex medical cases. The specialists at MU-Varna have sufficient experience and expertise to perform implants, and this 3D printer, which has been installed and is already in operation at the university, will provide an opportunity to improve the quality of patient care.